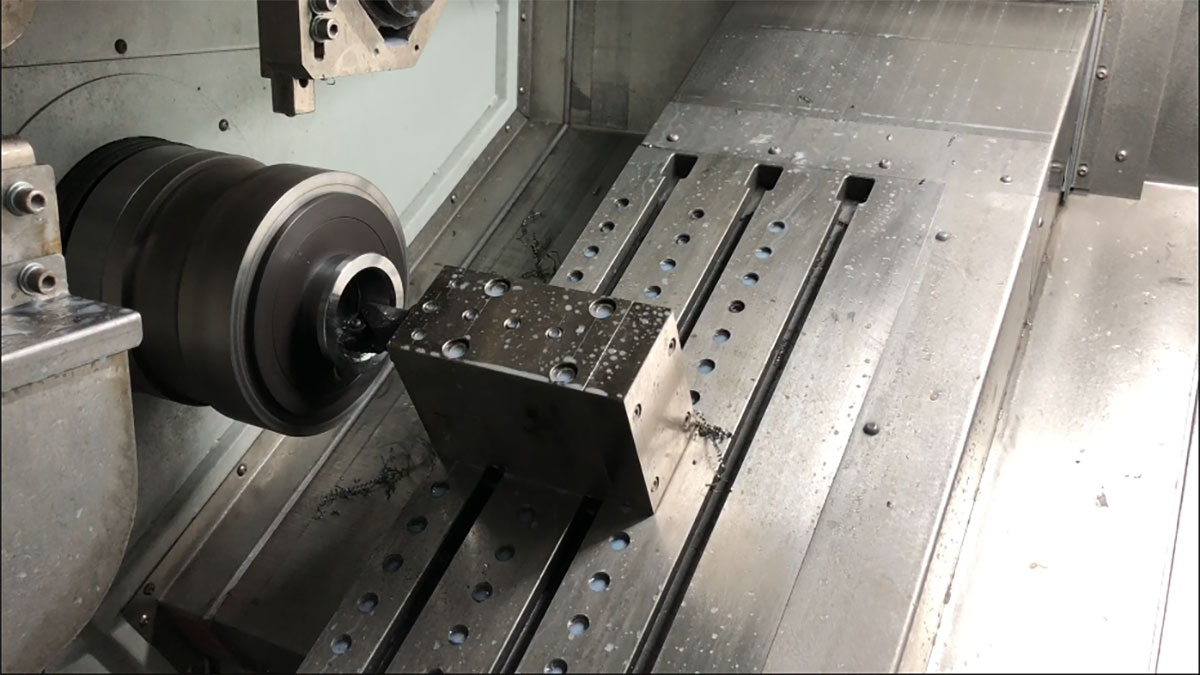

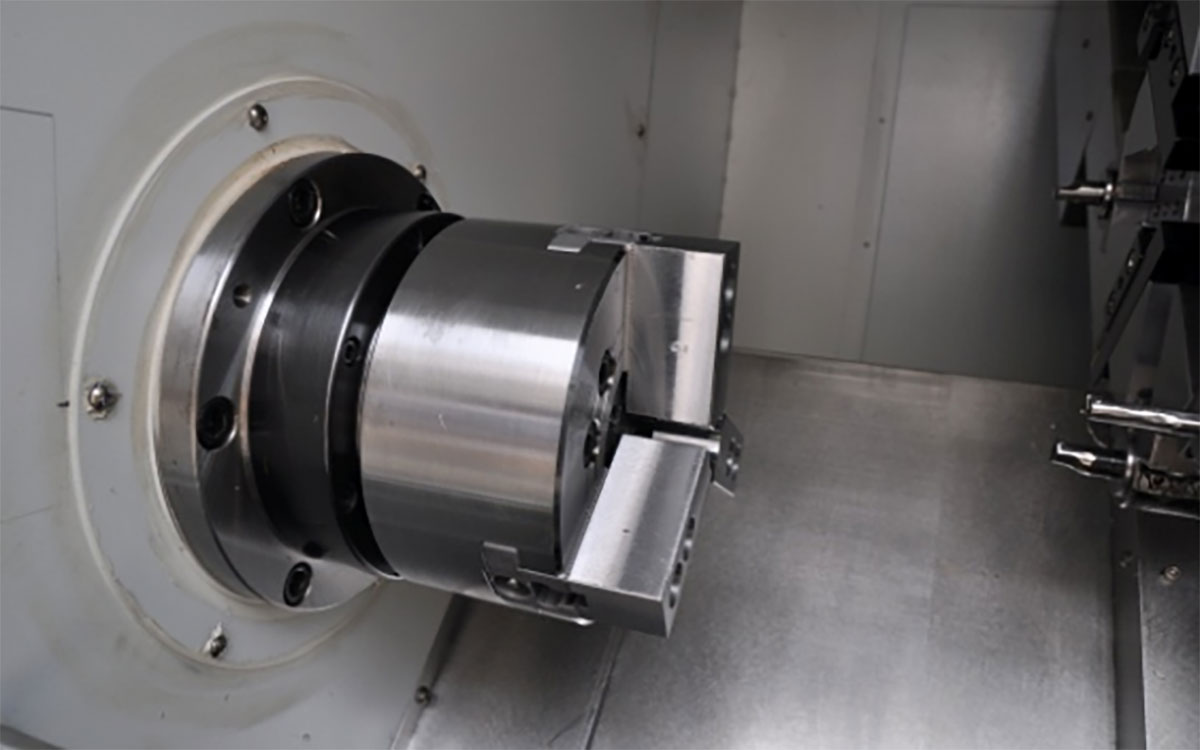

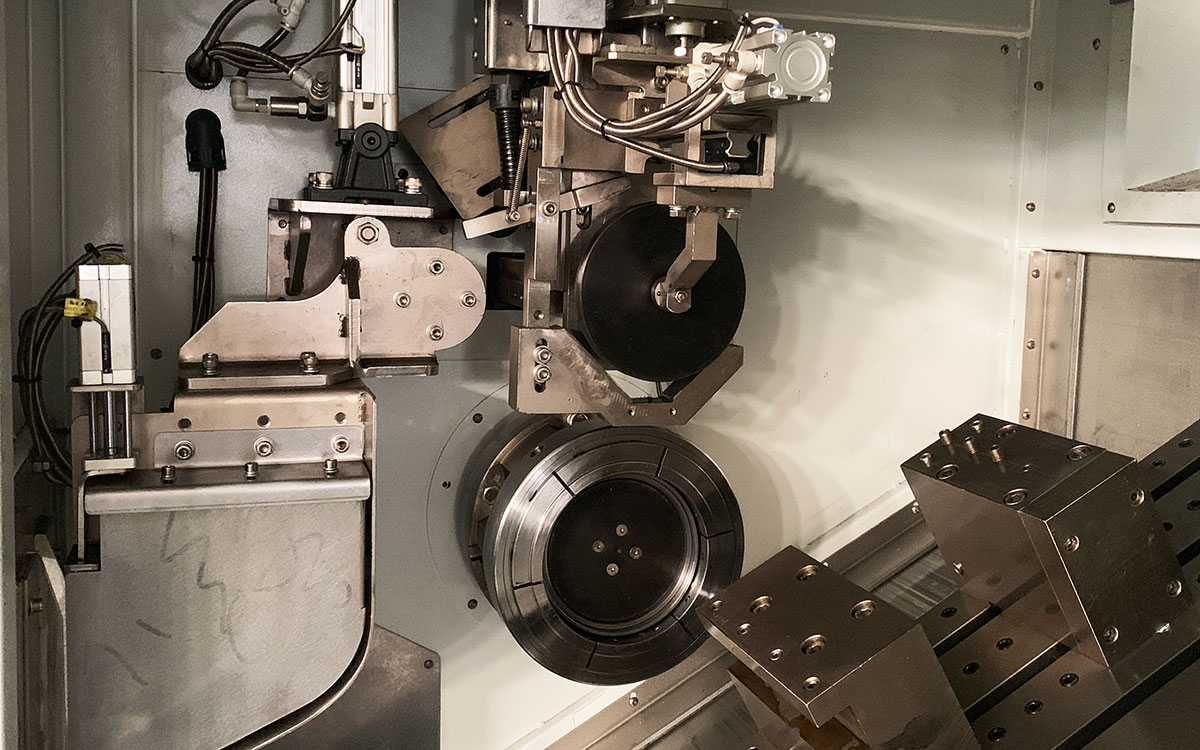

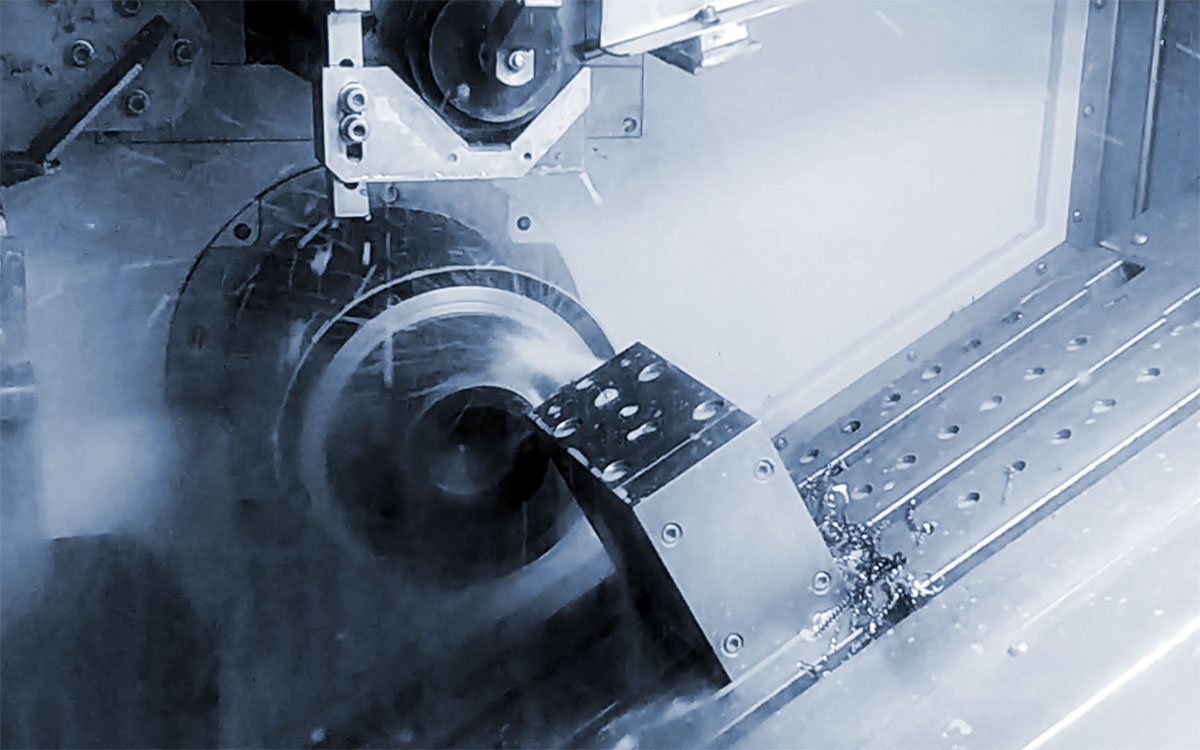

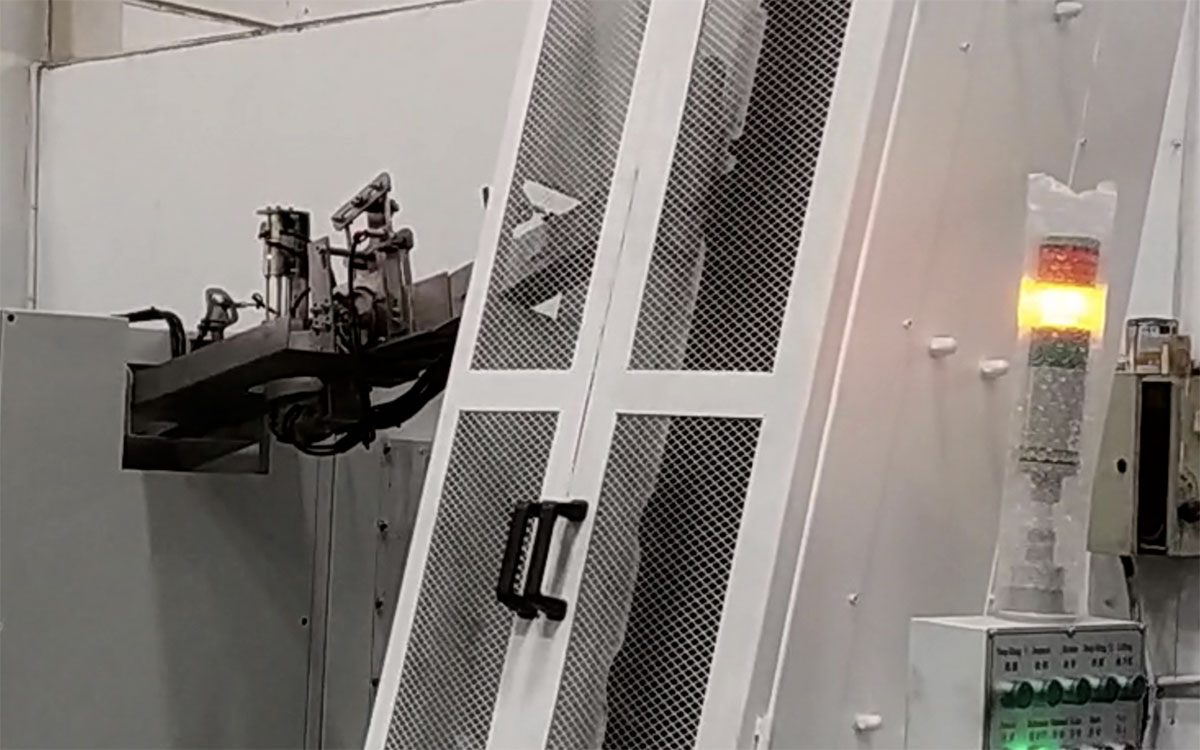

Automatic CNC Lathes with Inclined Rail Connection

DKCK-M5 Automatic CNC Lathe

The DKCK-M5 Automatic Lathe is a powerhouse machine engineered for high efficiency, precision, and durability. With its robust structure, this lathe excels in turning forging blanks and is the best choice for machining complex shaft and ring parts, automobile parts, bearing ring parts, sleeve parts, flange parts, and more. Designed for high productivity and precision, the DKCK-M5 combines advanced features and state-of-the-art technology to deliver exceptional performance.