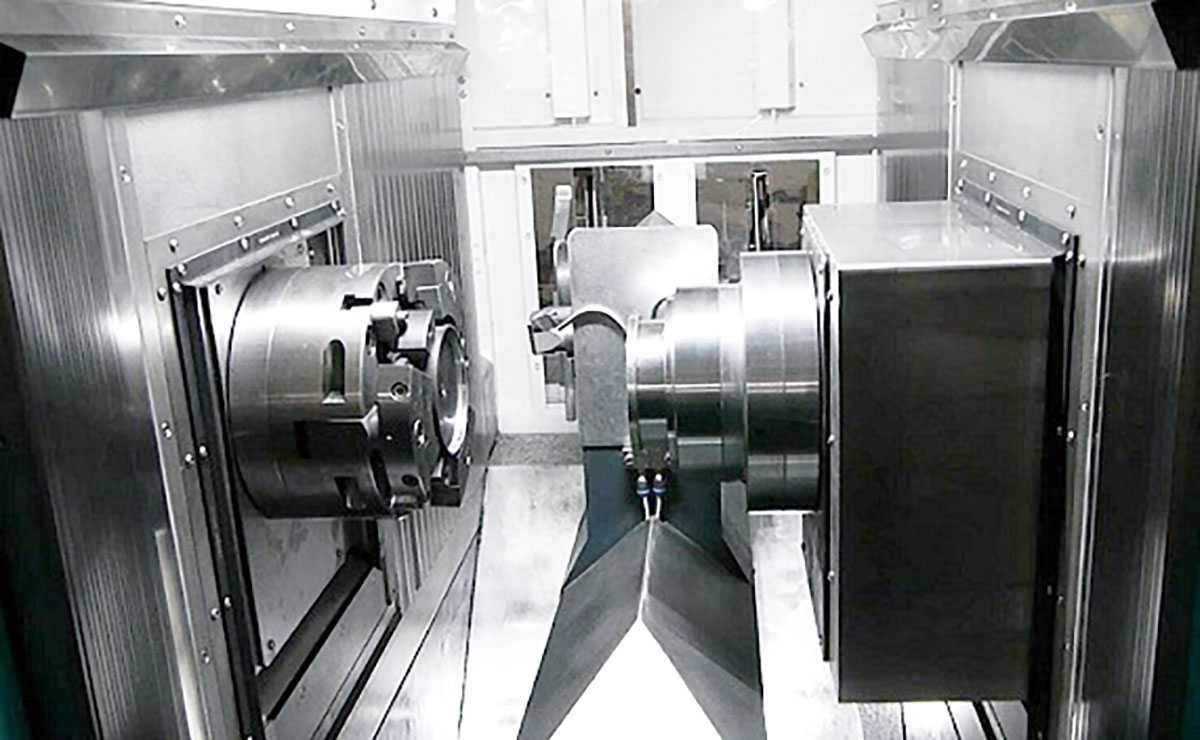

Double Spindle CNC Lathe

Double Spindle CNC Lathe (DKCK-ST80)

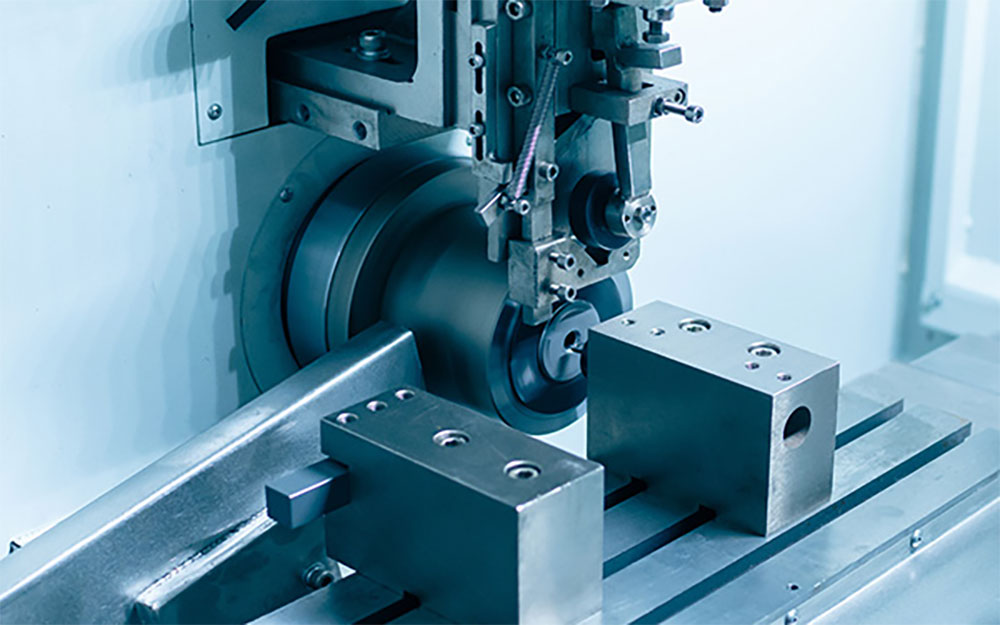

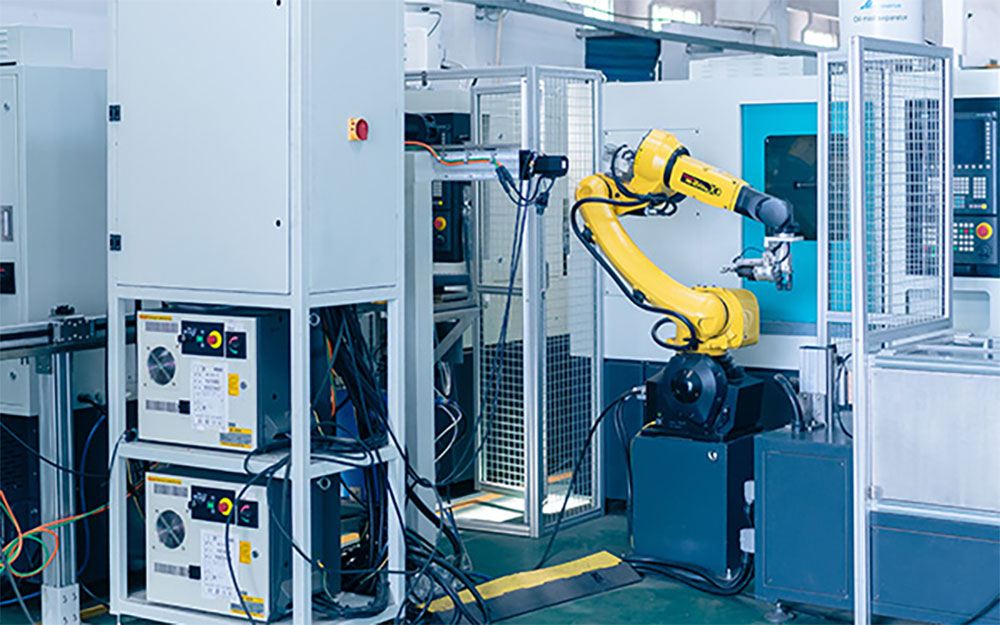

The DKCK-ST80 Double Spindle CNC Lathe is a high-precision, advanced machining solution designed to deliver exceptional performance and efficiency. Equivalent to two high-precision CNC lathes, this model is integrated with an automatic loading and unloading conveyor, ensuring seamless and efficient operations. The compact design optimizes workspace utilization while minimizing the risk of workpiece damage, saving energy, and boosting productivity.