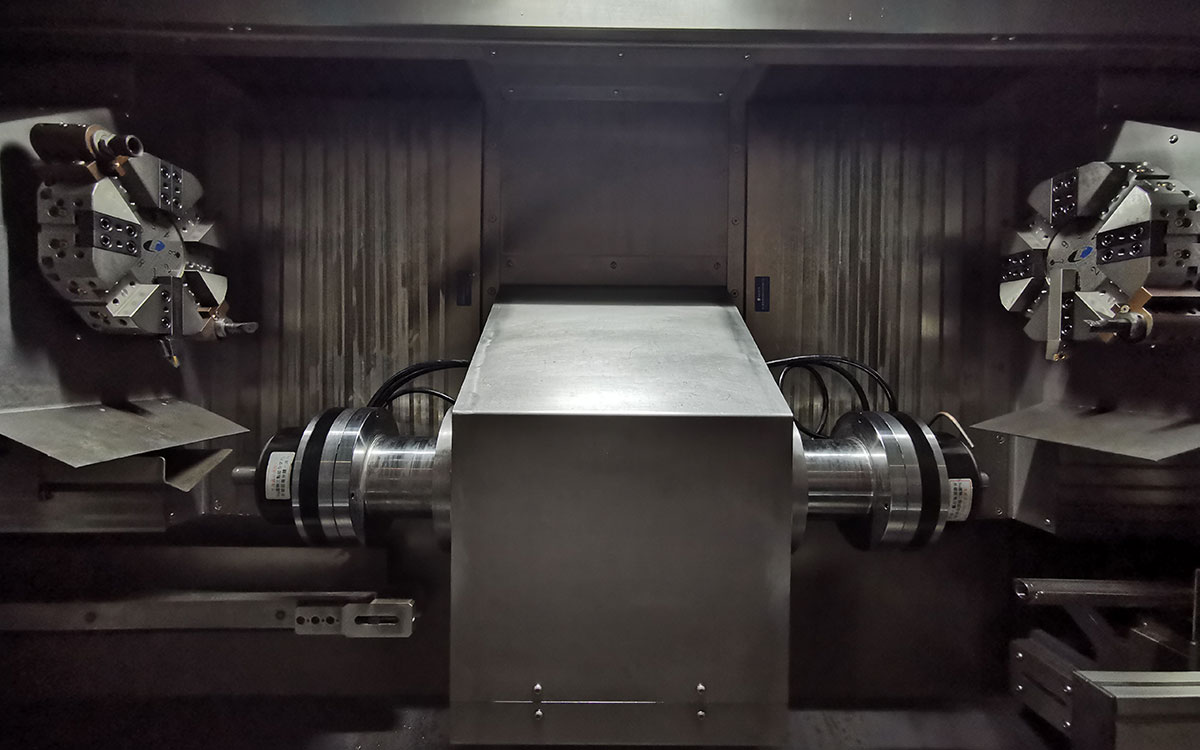

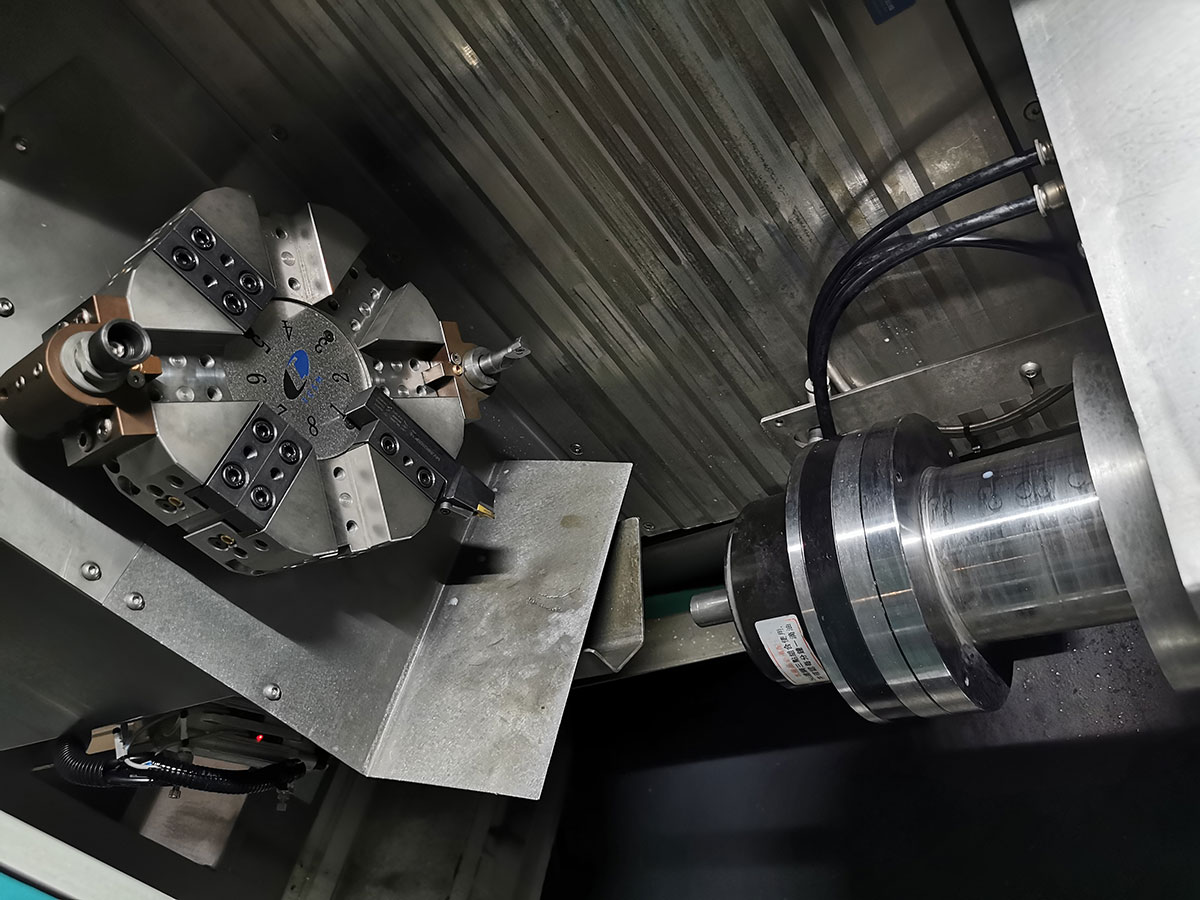

Double Head Lathes

DKCK-DE1200 Double-Head Lathe

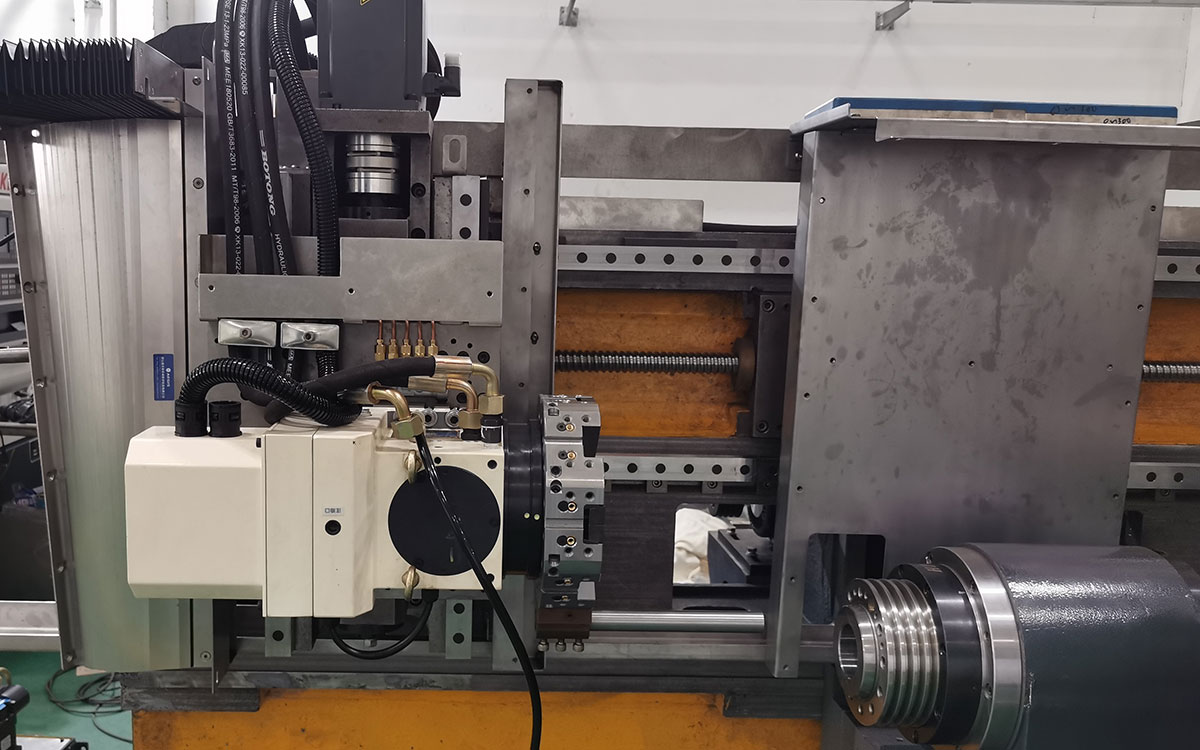

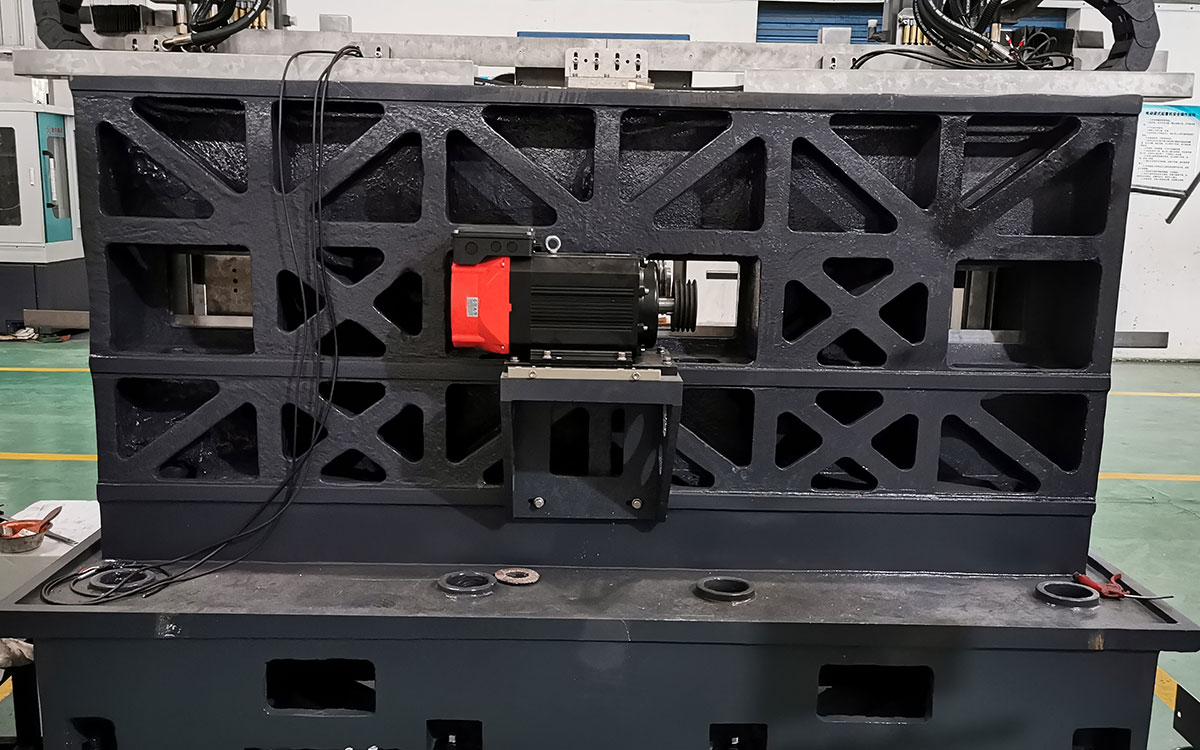

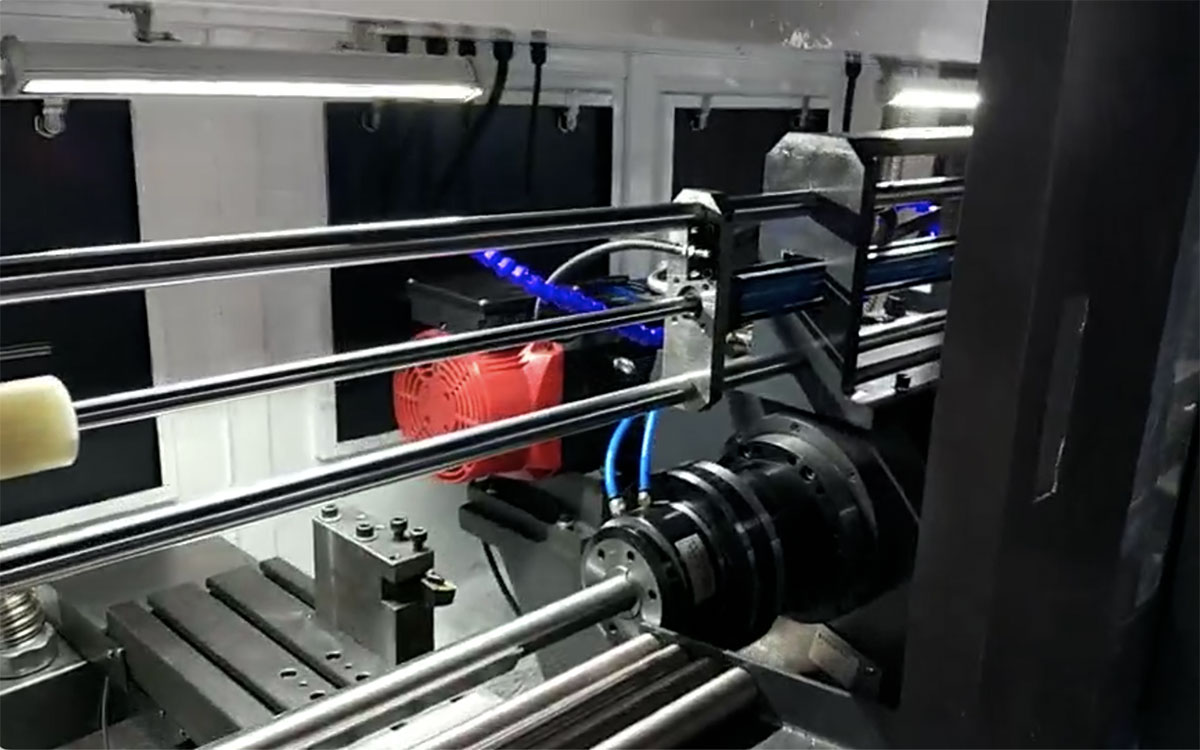

The DKCK-DE1200 Double-Head Lathe is expertly designed for the efficient processing of longer bars or pipe parts, ensuring high coaxiality at both ends. This advanced lathe features a unique configuration that enables simultaneous processing of both ends of the workpiece, significantly enhancing precision and productivity.