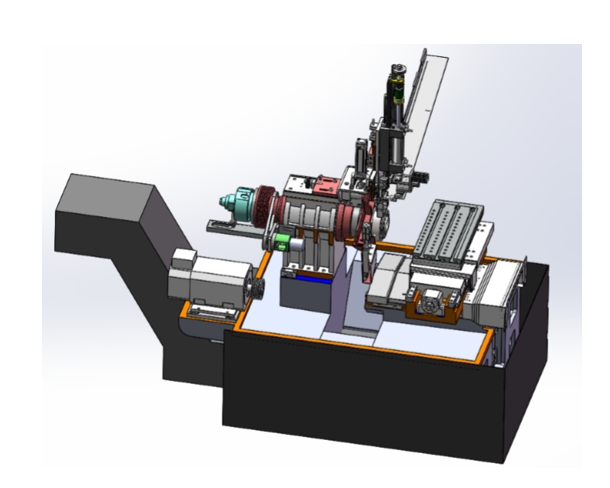

Automatic Numerical Control Lathes with Flat Rail Connecting Line

DKCK-LF35 Series Automatic CNC Lathe

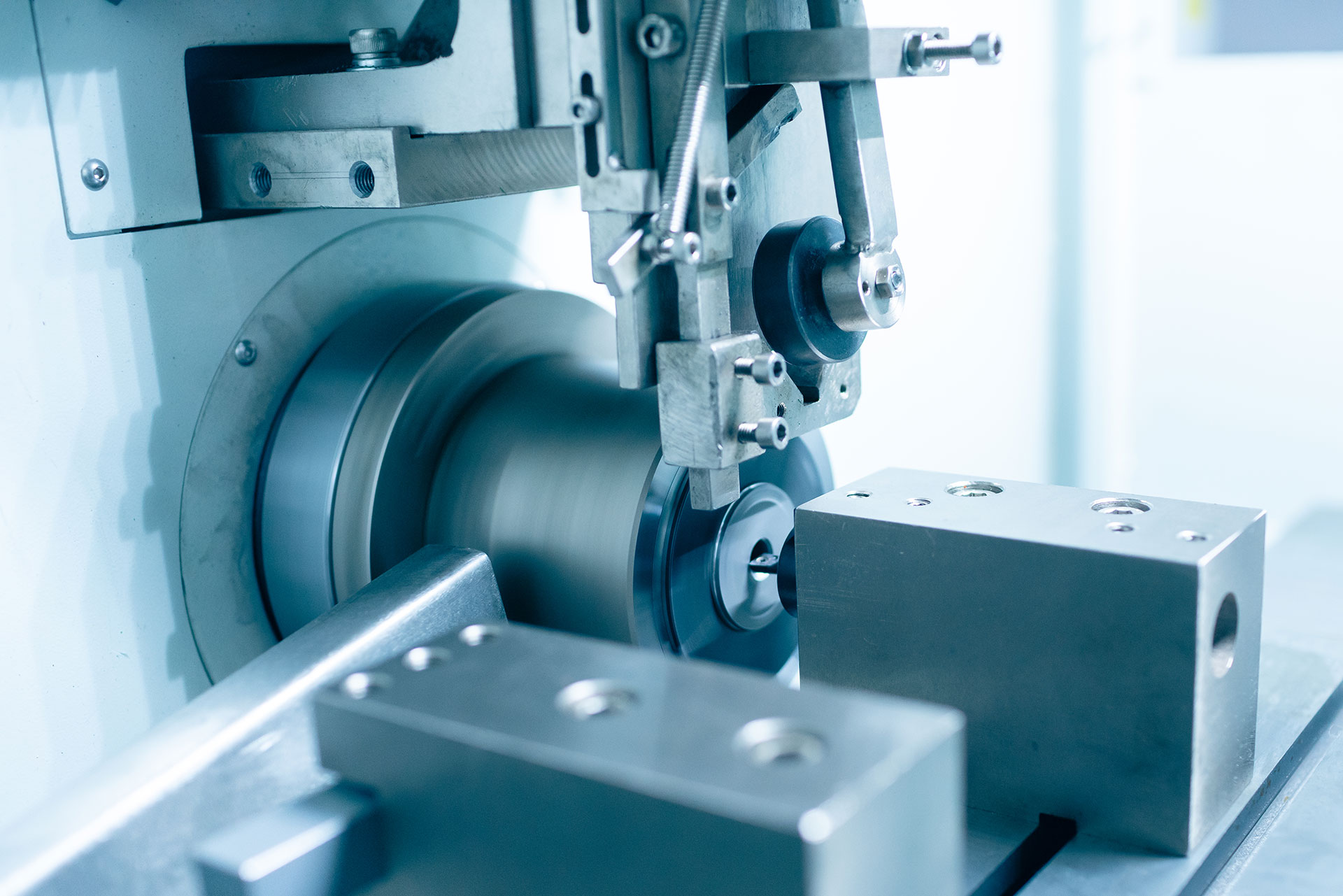

The DKCK-LF35 series automatic CNC lathe is designed for precision machining of automotive parts, bearing rings, complex shafts, and ring parts, adhering to exacting technical specifications set by FAG.