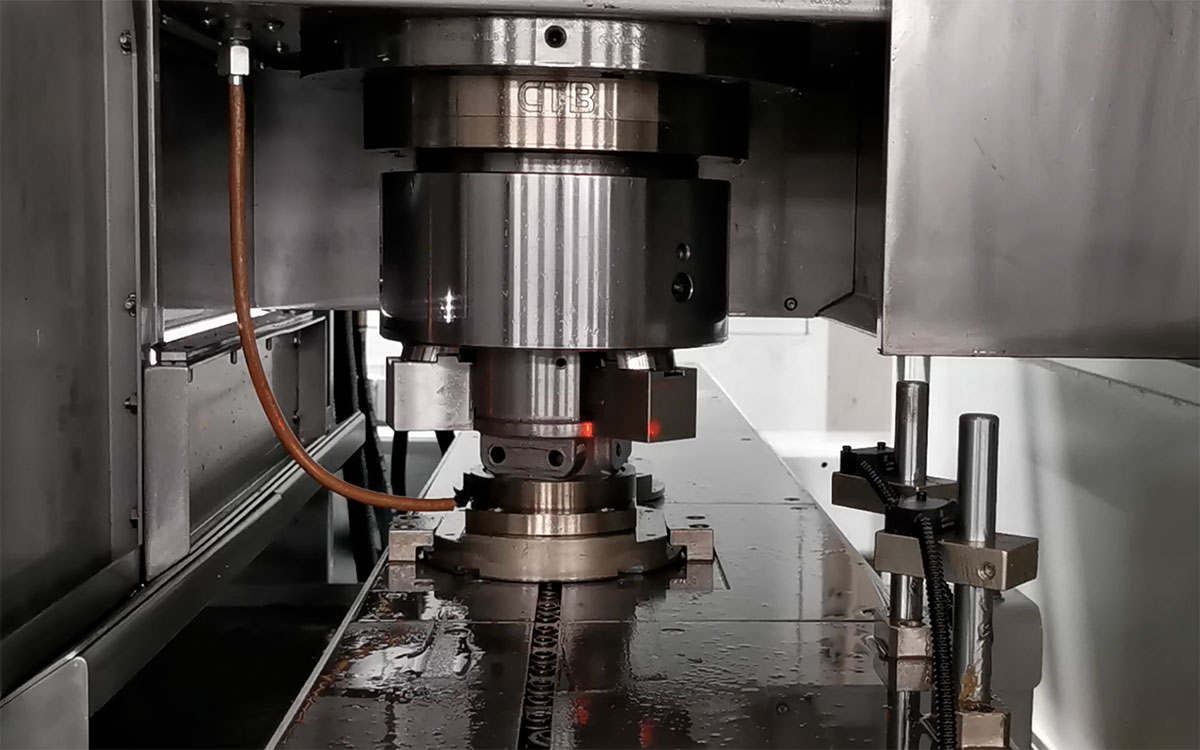

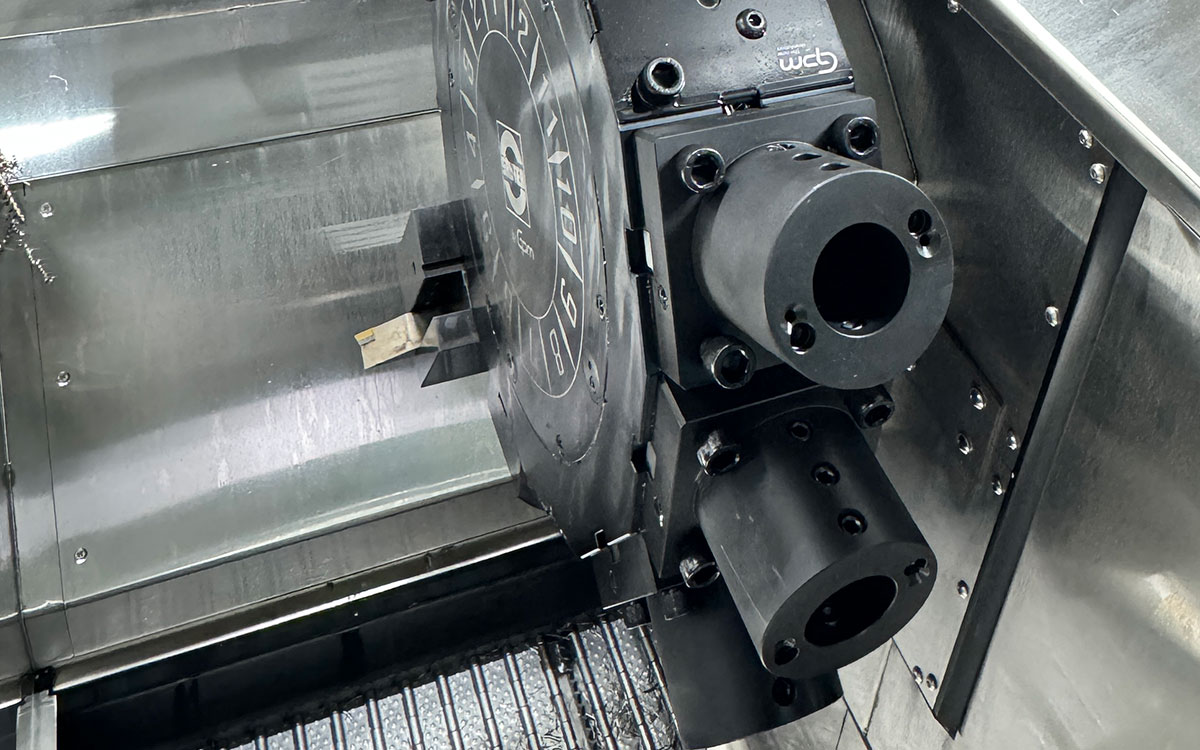

Vertical Turning Centers

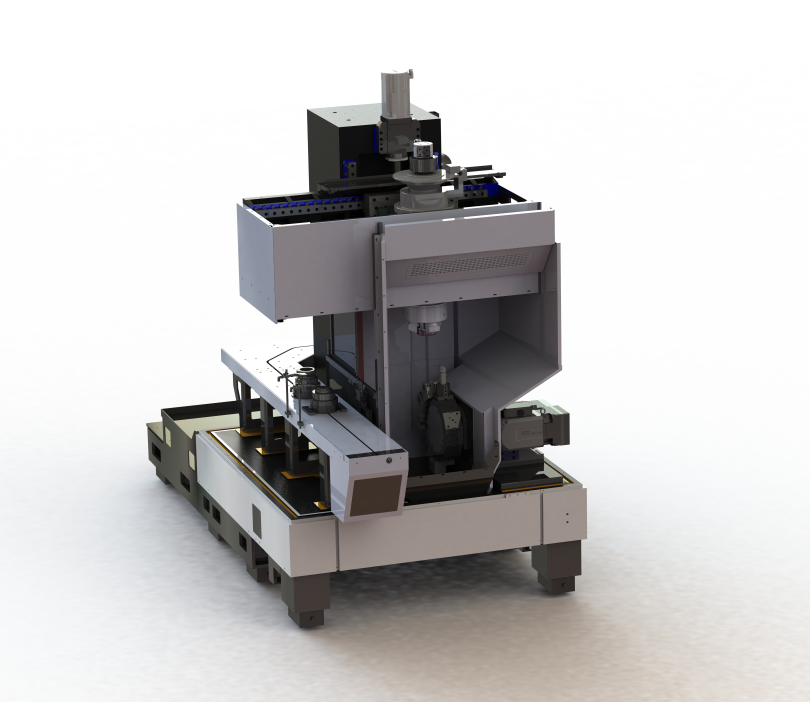

DKCK-DL5 Vertical Turning Center

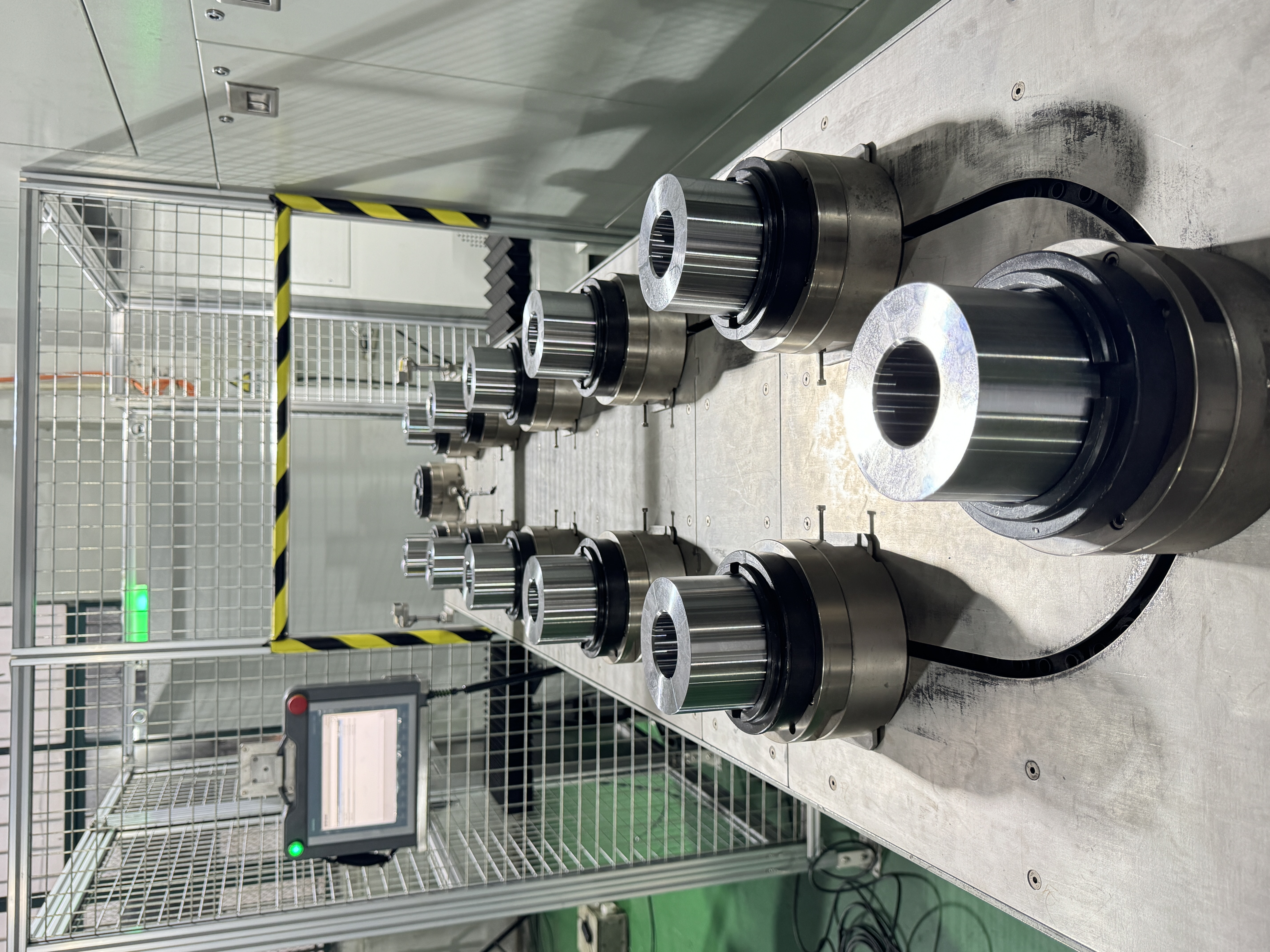

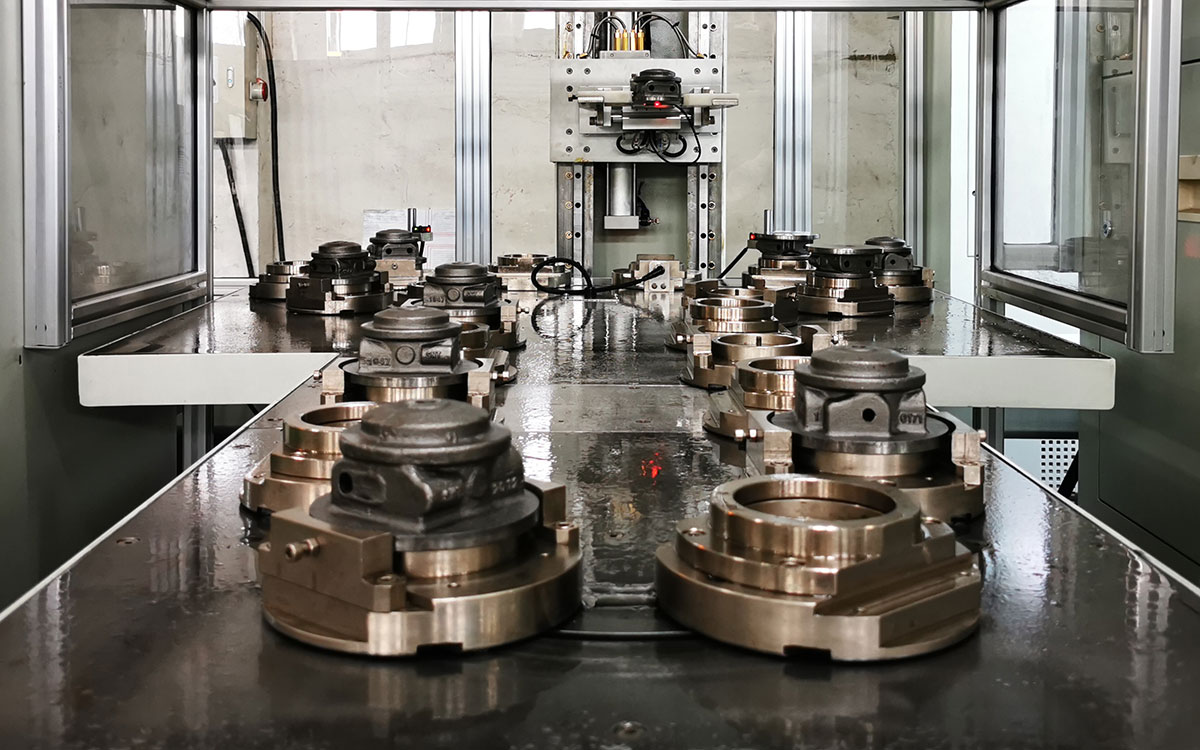

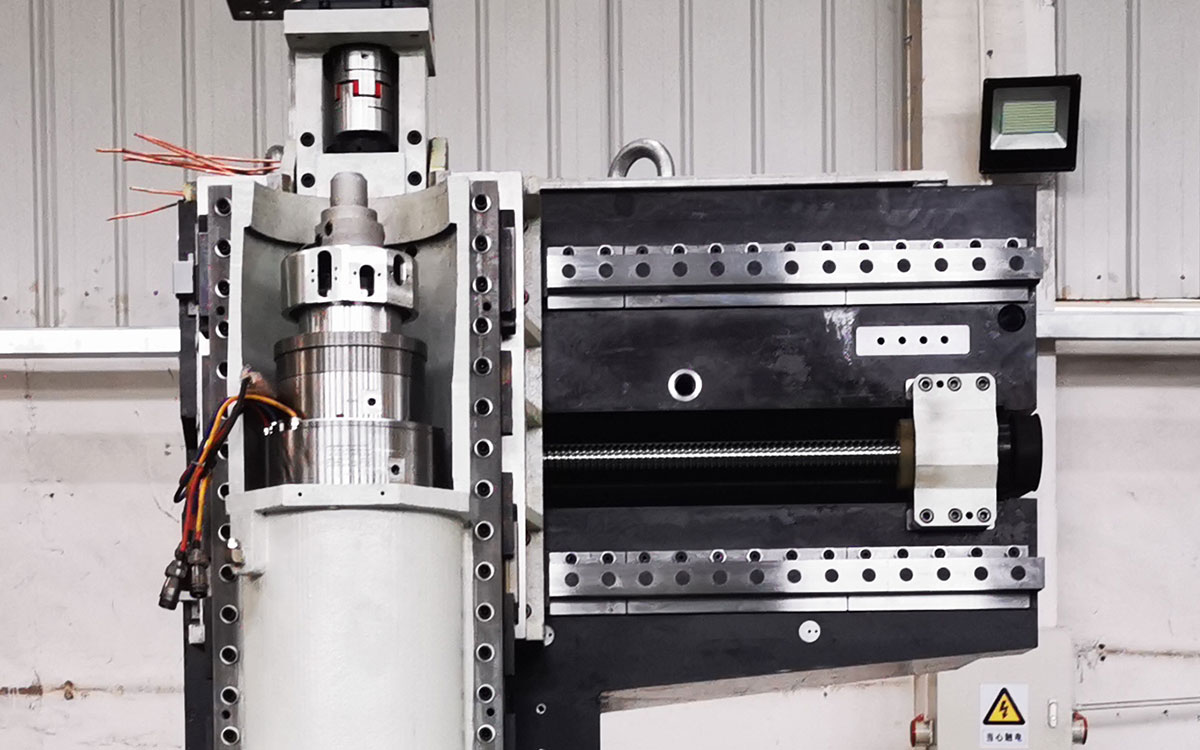

The DL5 Vertical Turning Center is an advanced machining solution capable of handling workpieces with a maximum diameter of up to 300 mm. As part of DIKE's modular turning center series, the DL5 stands out with its exceptionally compact design and integrated pick-up automation system, making it a perfect fit for modern manufacturing facilities with limited space.