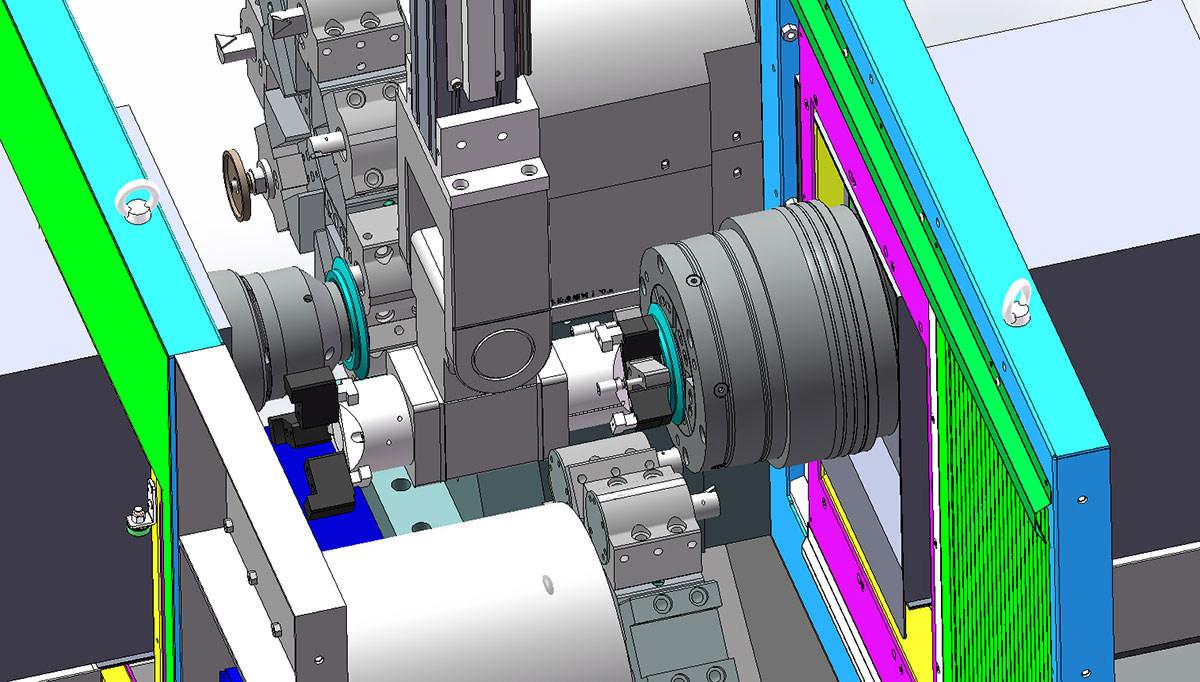

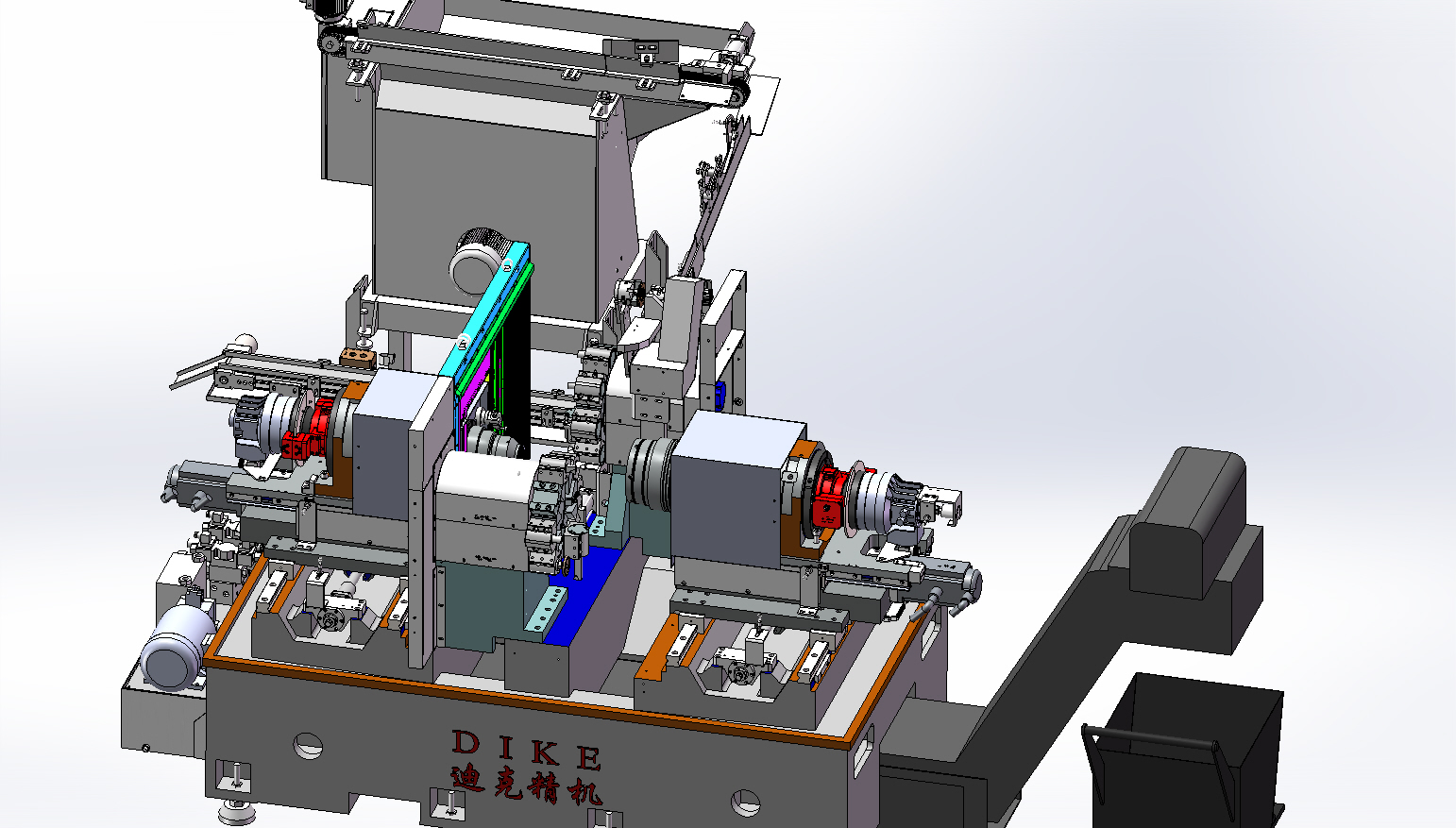

Double Spindle Double Turret CNC Lathe

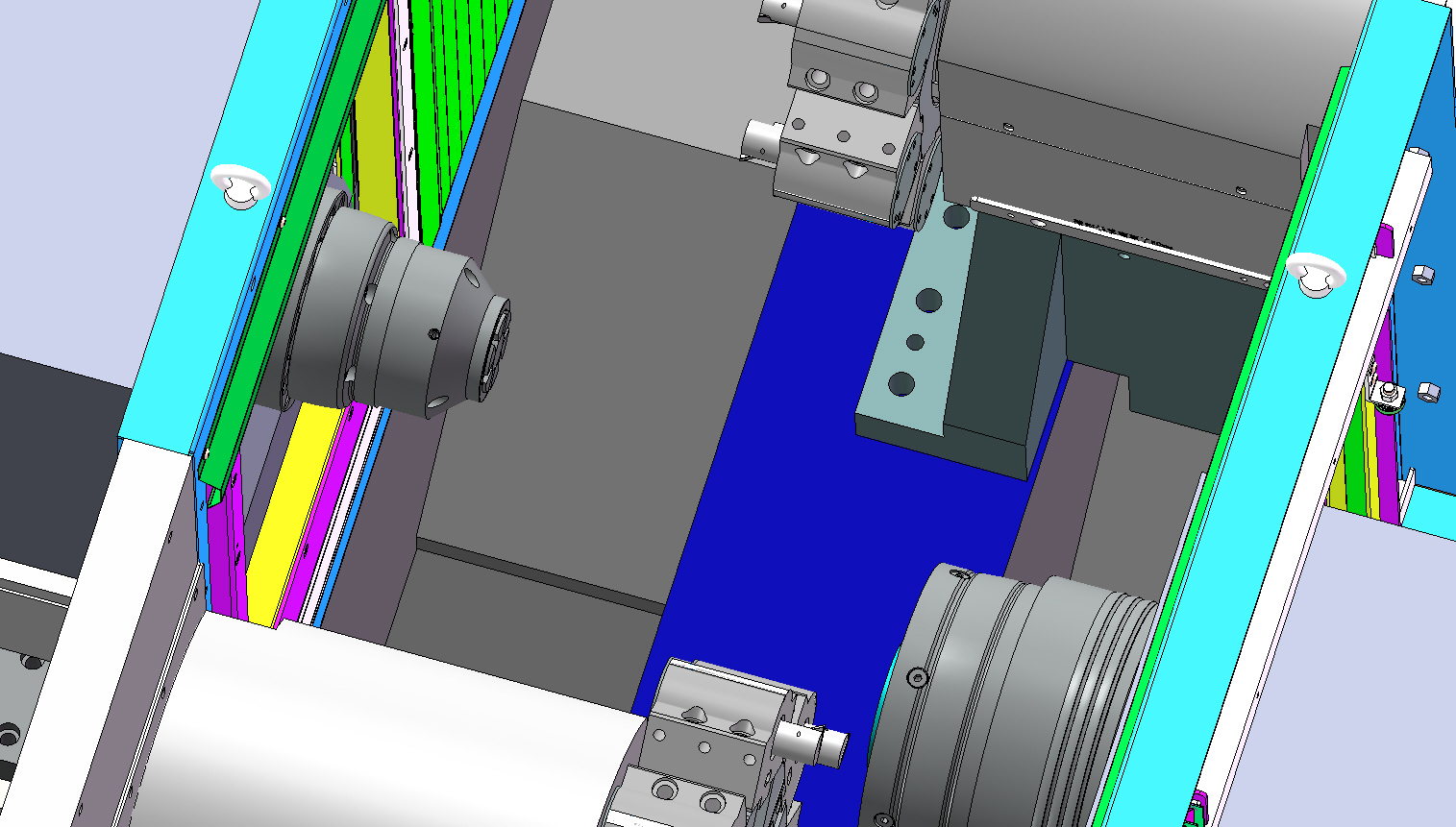

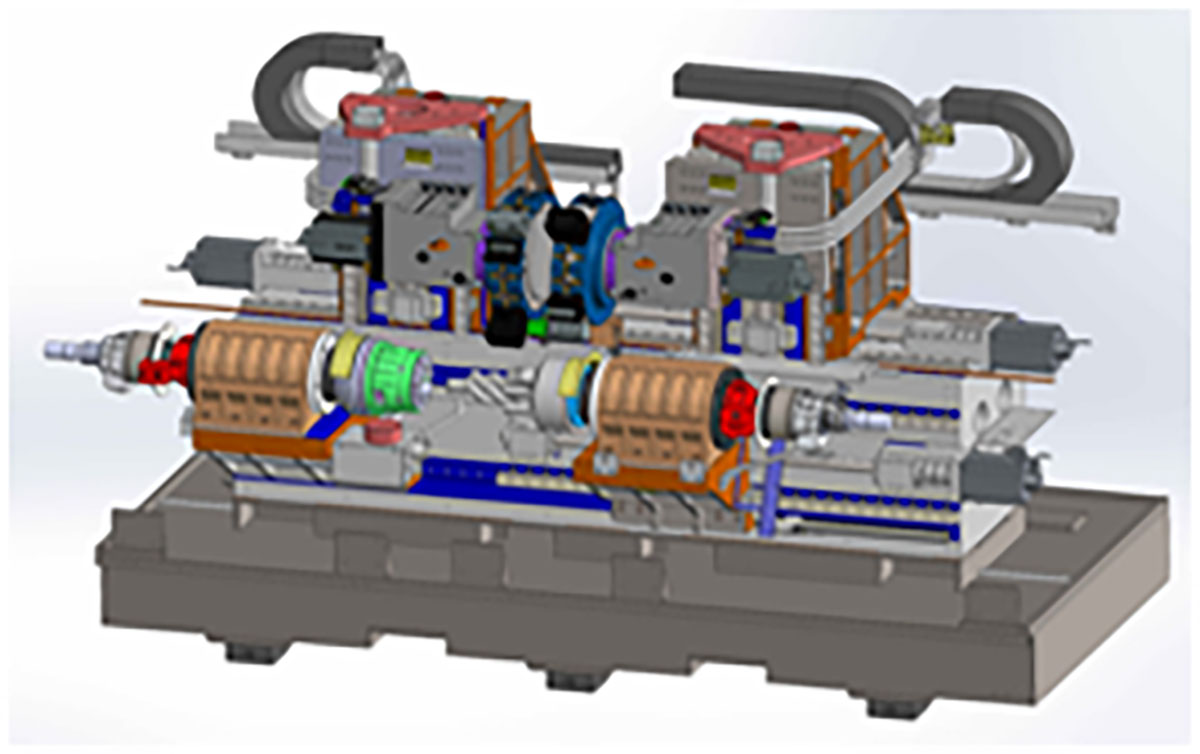

DKCK-C100 Series Double Spindle Double Turret CNC Lathe

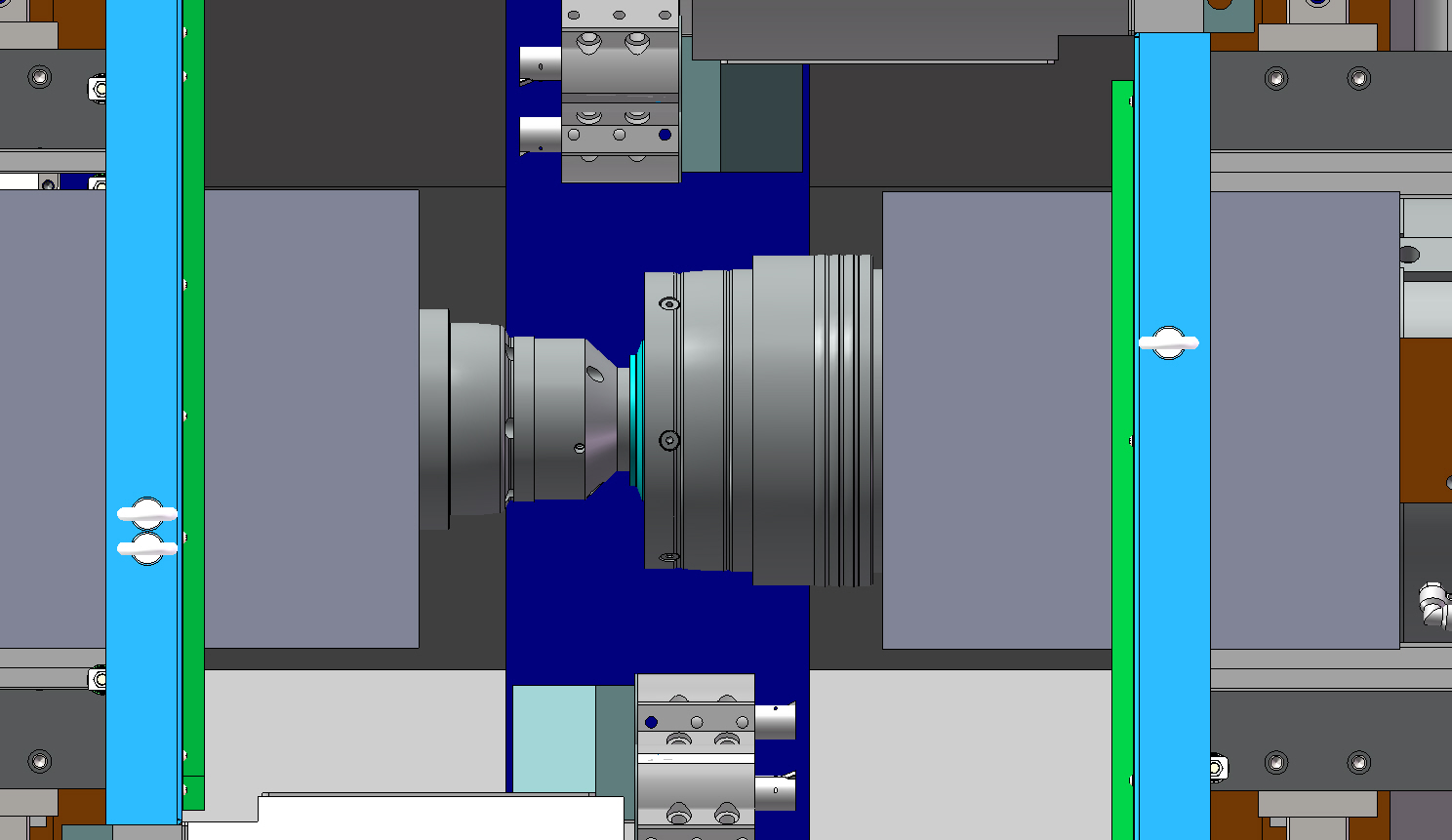

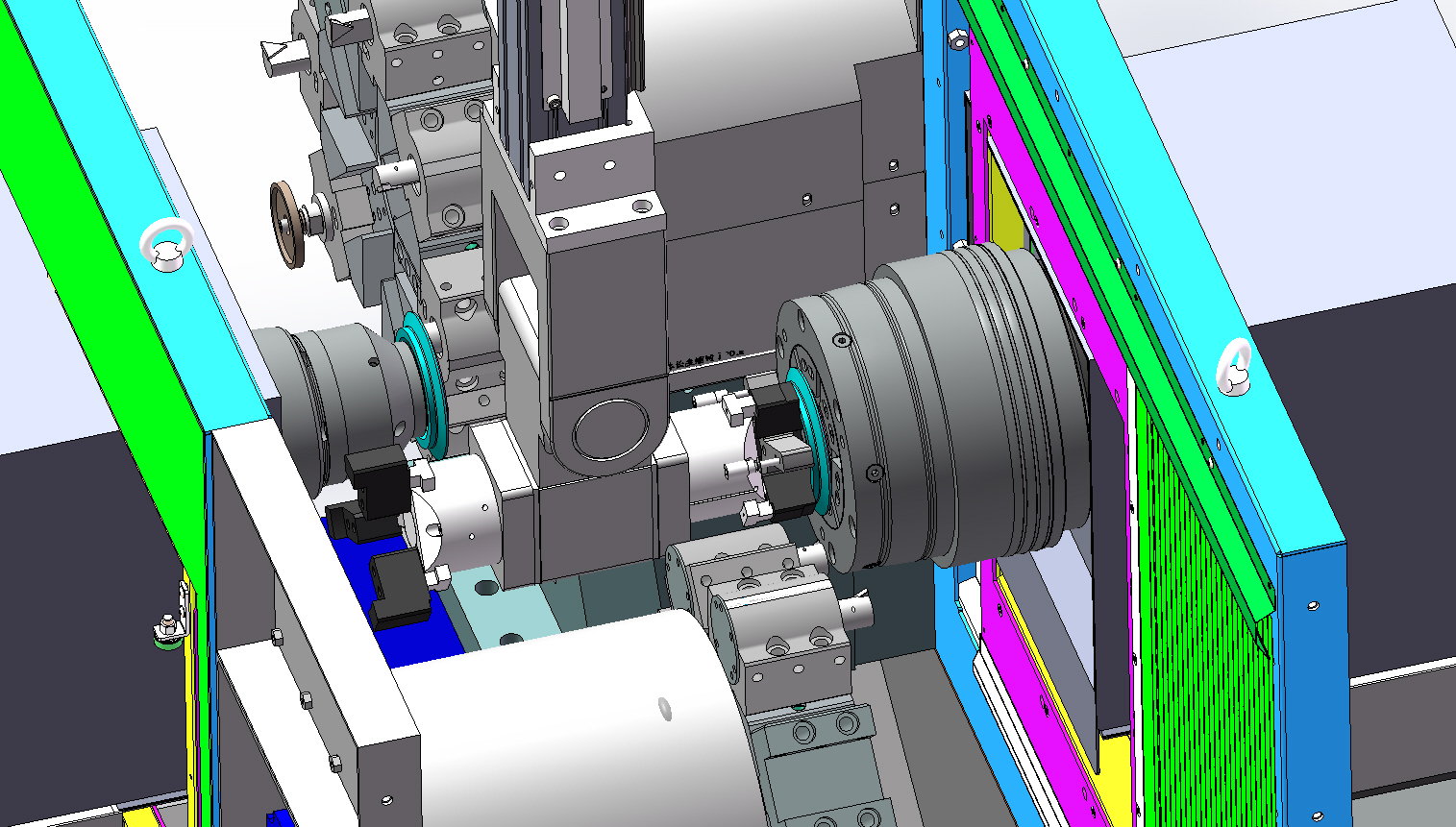

The DKCK-C100 Series Double Spindle Double Turret CNC Lathe is a state-of-the-art compound CNC lathe designed to meet the demanding needs of modern manufacturing. Featuring two spindles and two back turrets, this advanced machine supports simultaneous turning, milling, drilling, tapping, and grinding processes. Equipped with both Y axis and grinding wheel, it delivers exceptional versatility and precision.

The innovative double spindle design allows for automatic workpiece surface changes, significantly enhancing processing efficiency and accuracy. This CNC lathe is ideal for complex machining tasks, ensuring high productivity and superior quality.