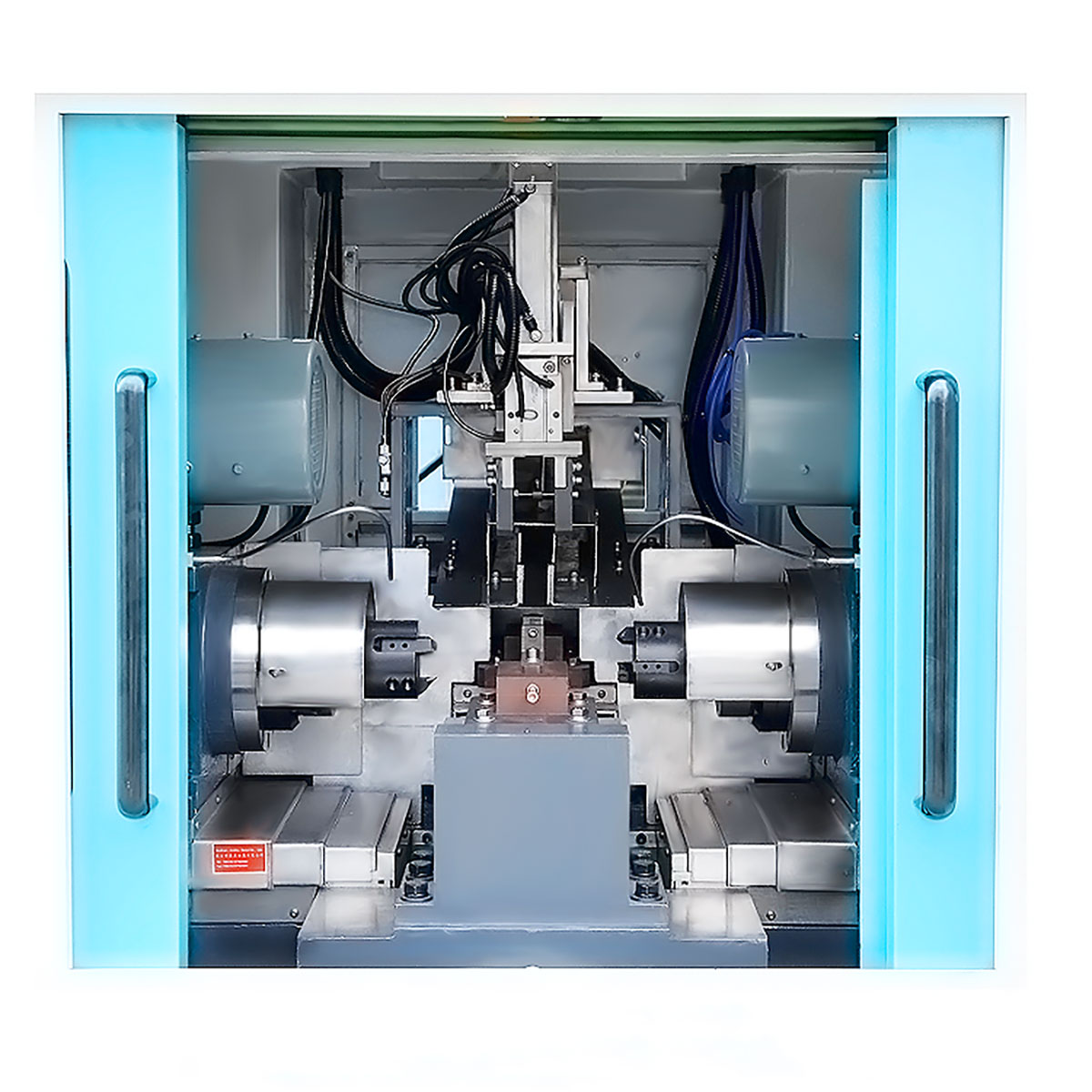

Double Head Chamfering Machines

DKCK-SMD Fully Automatic CNC Double-Head Chamfering Machine

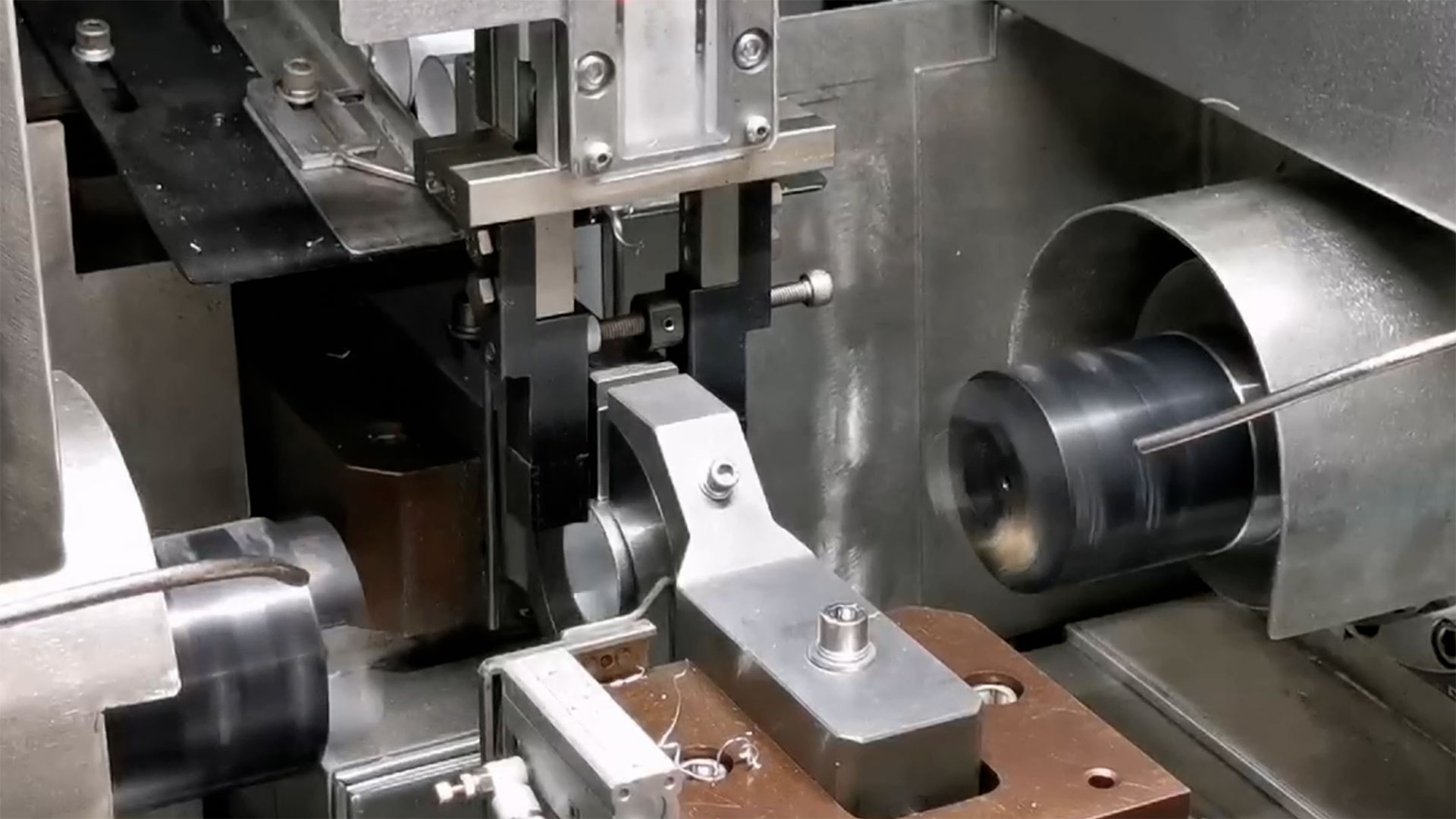

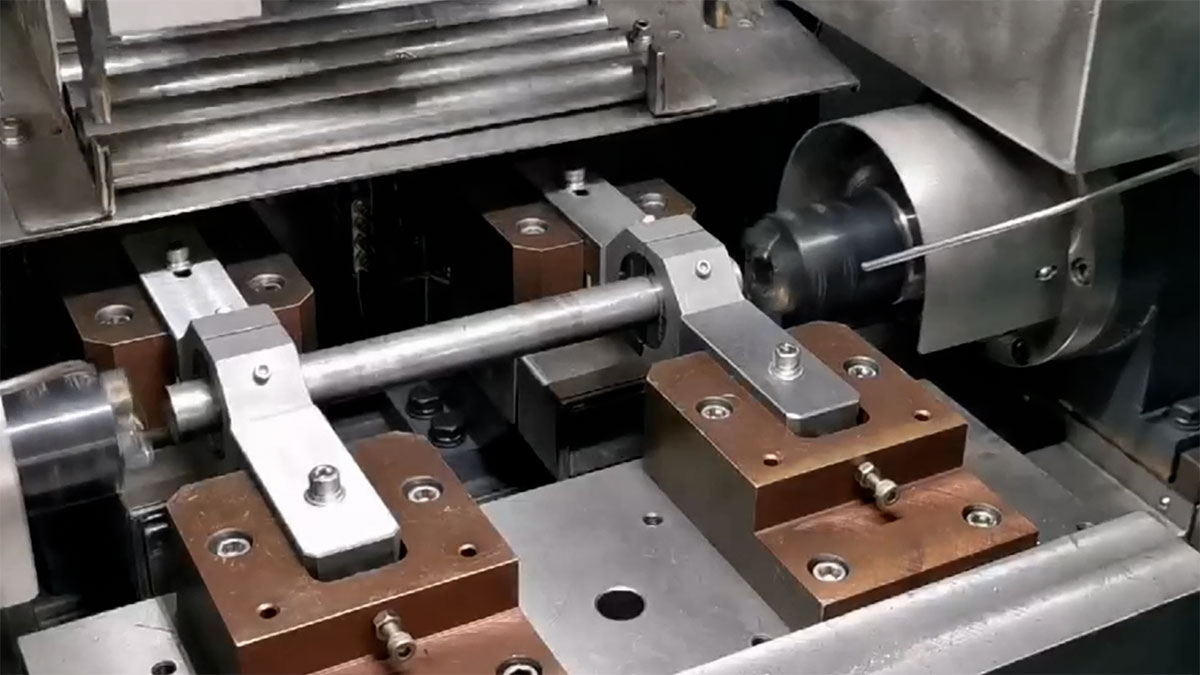

The Fully Automatic CNC Double-Head Chamfering Machine is expertly engineered for high-efficiency batch machining of auto parts. Equipped with the Siemens control system, this advanced machine integrates a servo system for precise control of the feeding device, and features specialized blade and clamp changing mechanisms. Its robust design and superior automation capabilities make it an ideal choice for large-scale manufacturing environments